Semiconductors are an essential part of our modern world and will play a decisive role in the future. They are the basis for developing technology such as smartphones, computers, electric vehicles, renewable energies and artificial intelligence. Temperature control plays a decisive role in semiconductor production to meet the highest demands for precision and efficiency. To overcome the challenges faced in microchip manufacturing, LAUDA offers innovative temperature control solutions.

Wafers form the foundation of modern electronics. These thin slices of high-purity semiconductor material, such as silicon, are used as a basis for manufacturing microchips. The quality and purity of wafers are crucial for the performance of the components mounted on them.

Find the right device for your application

Are you looking for the right temperature control solution for your application in the semiconductor industry? Then contact us today. Together with you, we will find the right solution for your application.

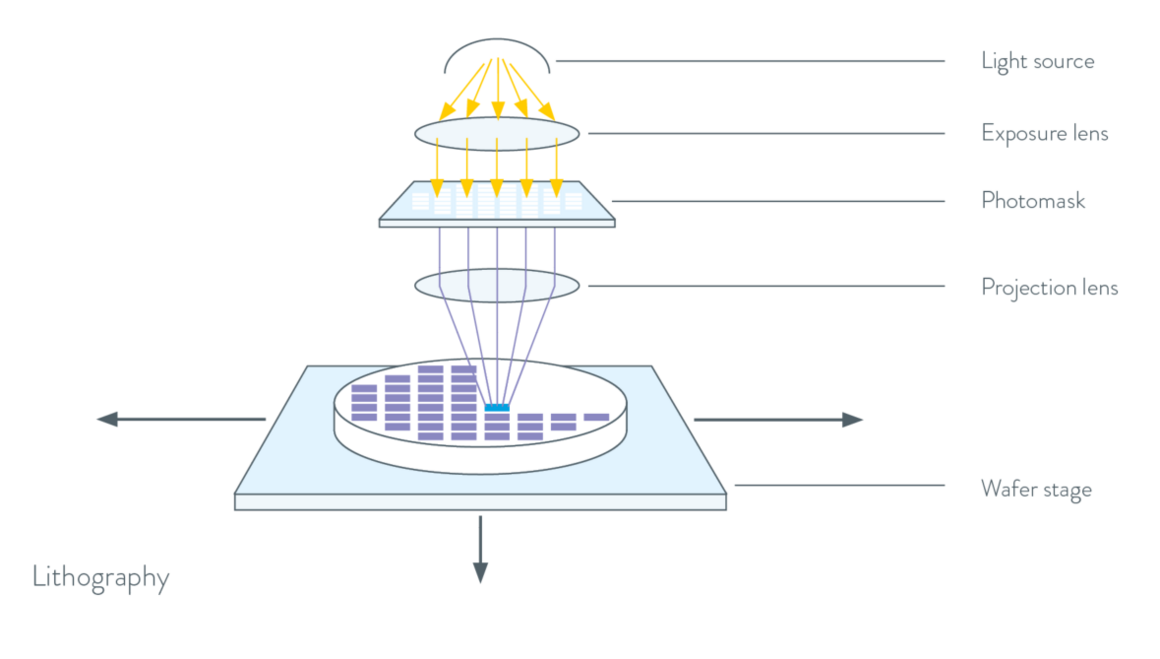

In lithography, UV light shines through a stencil and is demagnified to create a microscopic pattern on the wafer through the use of photoresist. Materials expand when heated and contract when cooled. This also applies to photomasks, exposure lenses and wafers in lithography. Even slight changes in temperature can alter the structure dimensions on a wafer, which can lead to dimensional variations that affect the accuracy and repeatability of the projected patterns.

The generation of a laser beam is produced by a huge amount of energy, which must be regulated in the form of waste heat. Reliable recirculating coolers such as the LAUDA Ultracool units prevent the laser module from overheating.

> LAUDA is your partner for the cooling of the laser generator.

The accuracy of wafer stages and measurement systems can be affected by operation and subsequent heat generation. Precision temperature control is required to avoid thermal expansion and ensure that positioning accuracy is maintained in the nanometer range.

> LAUDA is your partner for the cooling of the wafer stage.

Due to the high radiation power and high absorption of the lens, the system must be cooled substantially in order to maintain a constant temperature. Compact LAUDA devices counteract the deformation of optics and mirrors, which is essential for precise exposure.

> LAUDA is your partner for the cooling of the lenses / mirrors.

The turbo molecular pumps used in many applications consist of rotating blades that operate at extremely high speeds in order to create a high vacuum. These pumps generate heat through friction, which may cause damage or loss of performance without proper cooling. Cooling the vacuum pumps helps keep the operating temperature within the specified limits, which is essential for maintaining the required vacuum as well as the efficiency and reliability.

> LAUDA is your partner for the cooling of the vacuum pump.

In semiconductor production, plasma etching is a primary component for material removal in the manufacturing sequence. Plasma etch, also known as dry etch, is a process in which wafers are exposed to plasma in a vacuum etching chamber. The wafers are bombarded with the ions in the plasma to remove material. The temperature of the plasma influences the speed and efficiency of the etching process. In semiconductor production, it is important to control the temperature of the plasma with high precision, because the wafers are processed in the micrometer and nanometer range. Even slight changes in temperature can result in significant changes to the size and shape of the etched structures. LAUDA offers the specially designed Semistat for this sensitive process.

Thermoelectric process thermostats from −20 to 90 °C for the semiconductor industry:

Other advantages of thermoelectric constant temperature equipment

Metal-organic chemical vapor deposition (MOCVD) is a key technology in the manufacture of LEDs, lasers, transistors and solar cells. In this process, extremely thin, single-crystalline layers are applied to a wafer. The coating process occurs in a reactor chamber at temperatures above 1,000 °C, which requires effective heat dissipation. The temperature of the turbo molecular pumps for vacuum generation and the bubblers containing the gaseous precursors must also be maintained constant. LAUDA offers an extensive range of products for the various temperature control tasks of an MOCVD system.

Find the right device for your application

Are you looking for the right temperature control solution for your application in the semiconductor industry? Then contact us today. Together with you, we will find the right solution for your application.

CMP – a process for surface smoothing by combining chemical and mechanical processes. In the different production steps of a microchip, the surface of the wafer must be smoothed to perfection. Chip manufacturers use a process called chemical mechanical planarization (CMP) to achieve this. CMP removes and planarizes excess material on the front of the wafer by exerting forces of pressure precisely to the back of the wafer and pressing the front against a rotating pad made of special material that also contains a combination of chemicals and abrasives. In order to guarantee the precision of this process, the temperature of the polishing fluid must be precisely controlled and the resulting heat must be dissipated from the sanding pad, which is where LAUDA constant temperature equipment comes into play.

Precision temperature control is essential in maintaining the quality and reliability of the CMP process.

The right temperature ensures that cleaning chemicals work effectively and integrity of the wafer is not compromised.

At the start of the CMP process, the polishing components must be heated to the correct process temperature. The temperature of the components must then be maintained constant during the process to ensure process reliability and prevent any stress on the wafers. The high heating capacity of LAUDA's ITHW systems allow users to quickly reach their desired process temperatures, while the high cooling capacity allows for ample heat dissipation during the polishing process.

The slurry must be maintained at the required temperature to ensure the reaction rate and efficiency of the slurry material.

> LAUDA is your partner for the temperature control of the polishing disc as well as the polishing slurry.

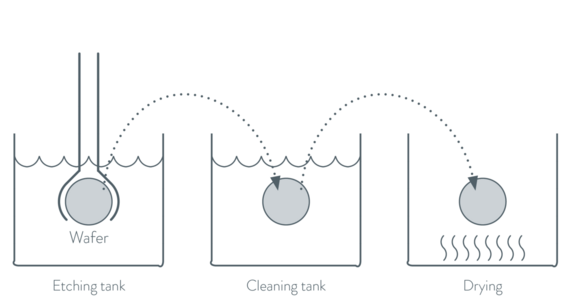

Wafer cleaning – removal of chemical and particulate contaminants without altering or damaging the wafer surface or substrate.

The cleaning of wafers is essential in ensuring a high yield rate in semiconductor production, since more than a third of all manufacturing steps are dedicated to cleaning alone.

Up to 200 cleaning steps may be required for state-of-the-art memory chips, such as a 20 nm Node DRAM.

Temperature control technology is essential in ensuring that a constant temperature is maintained during cleaning to optimize the efficiency and effectiveness of the cleaning process. Our advanced temperature control technology minimizes the risk of contamination and improves the reliability of semiconductor products by ensuring a stable process temperature that maintains the integrity of the wafers and ensures the best preparation for subsequent production steps.

Temperature control of wash basins

Process temperature control for preventing wafer stress and maintaining the washing fluid at a perfect temperature.

> LAUDA is your partner for the temperature control of the washing fluid.

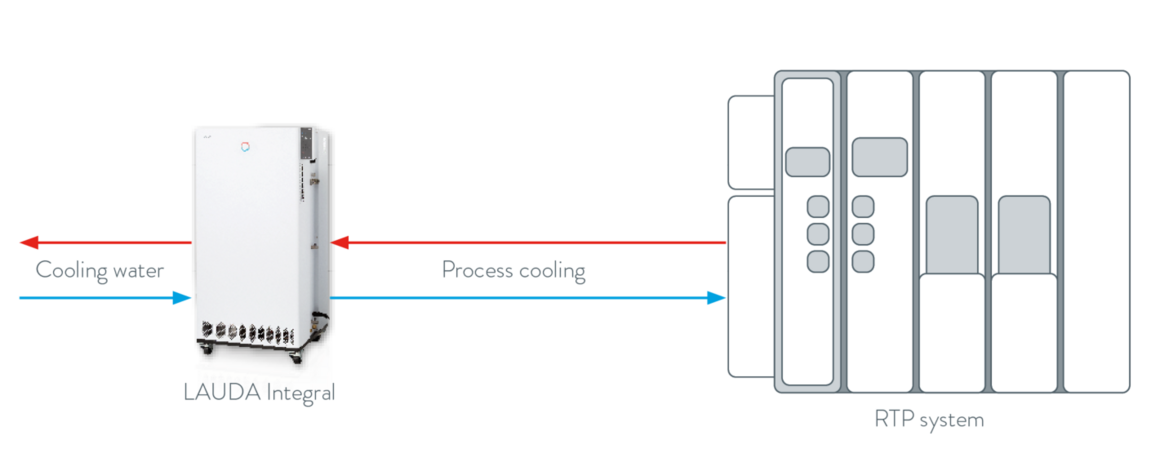

In the world of semiconductor manufacturing, Rapid Thermal Processing (RTP) systems play a vital role in the production of high-quality electronic components. RTP is a process in which wafers are exposed to extremely rapid, controlled temperature changes in order to induce specific chemical and physical changes in the material. The temperature control technology must be extremely precise to correctly adapt the properties of the semiconductor material. The efficiency and quality of these processes depend largely on the performance of the temperature control technology. In order to meet the complex requirements of temperature profiles, RTP systems use sophisticated temperature control technology that also incorporates heating and cooling systems.

Heating elements in RTP systems must be capable of reaching and maintaining high temperatures of up to 1,200 °C in just a few seconds.

Just as important as the heating process is the controlled cooling of the wafers after they have been heated up to 1,200 °C for a short time. For this purpose, dynamic temperature control units such as the LAUDA Integral series enable rapid heat dissipation without jeopardizing the quality of the wafer.

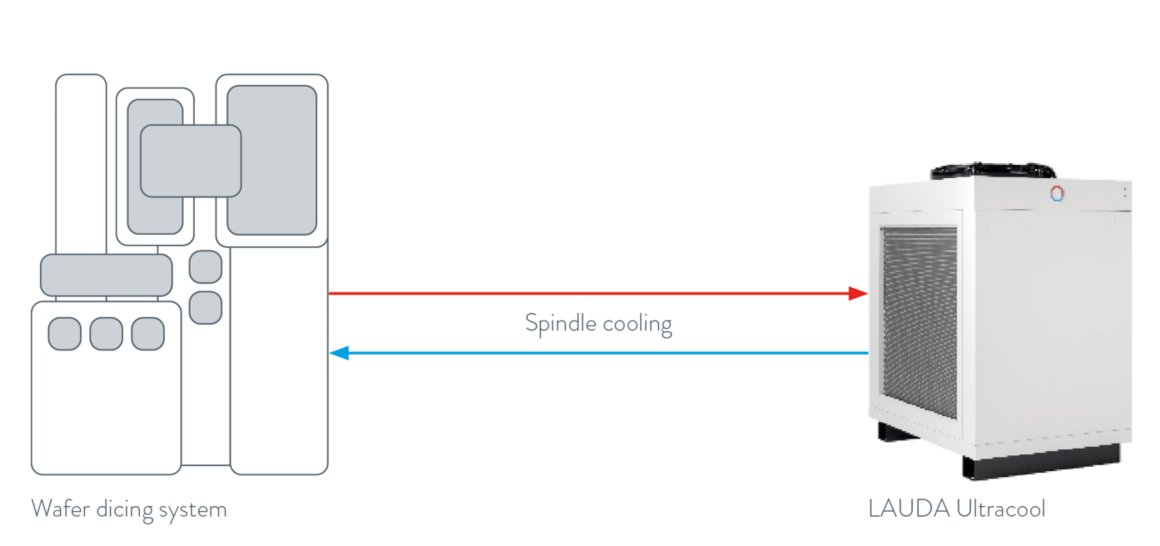

Various elements must be cooled during the wafer dicing process to prevent thermal damage and ensure the high quality of the chips. Some elements that may require cooling include:

Wafer surface: Cooling prevents heat damage and defects during the cutting process.

Blade dicing: Cooling reduces frictional heat and extends the life of the saw blade.

System components: Maintains machine performance by cooling heated parts such as motors and spindles.

Coolant jet: Dissipates heat and flushes particles away. Particularly important for blade dicing.

Laser dicing systems: Laser components require cooling to maintain efficiency and precision. Modern dicing systems have sophisticated temperature controllers for an efficient, high-quality dicing process.

The specific cooling requirements may vary depending on the dicing process used and must be adapted to maintain the integrity and purity of the wafer. Modern dicing systems incorporate complex temperature controllers to meet these requirements.

Chip testing systems use constant temperature equipment to thermally condition the chips during the testing process. This means that the chips are heated to specific temperatures to observe their operating behavior under different thermal conditions. The specific scenarios where constant temperature equipment is required include:

Temperature cycle tests: During these tests, chips are repeatedly heated and cooled to determine how they behave under conditions of thermal expansion and contraction.

Burn-in tests: These are stress tests where chips are tested at higher temperatures for longer periods.

Cold and heat tests: Chips are exposed to extreme temperatures that exceed normal operating temperatures in order to determine their operating limits.

Quality assurance and control: During the production phase, manufacturers must ensure that each chip meets the relevant requirements. Constant temperature equipment is used to ensure the constant and controlled temperature environment required for accurate, reproducible test results.

Temperature control is essential in ensuring that chips operate reliably in a variety of environments, especially in applications where temperature fluctuations are common, such as automotive, aerospace and consumer electronics. Modern temperature control systems must be extremely precise and capable of reacting quickly to changes in order to ensure that test cycles remain efficient and effective.

CPU temperature tests – Cooling systems for high quality assurance standards

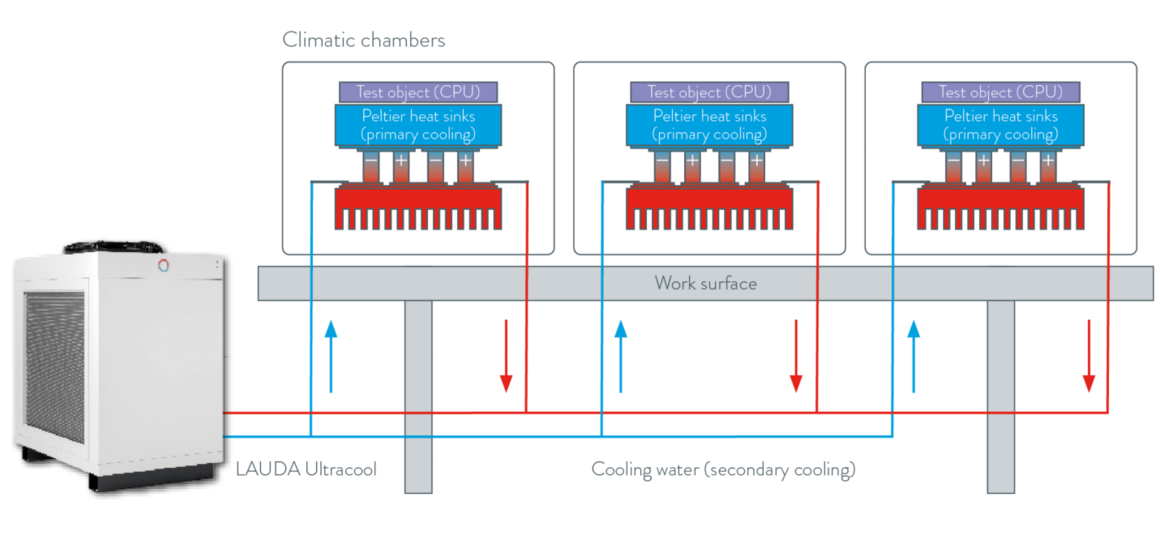

The semiconductor industry sets the highest standards of precision and reliability, especially when it comes to CPU quality assurance. Once manufactured, these powerful chips must undergo a series of demanding tests to ensure that they function correctly under different conditions. One crucial aspect of this process is the temperature tests conducted in specially designed climatic chambers. These chambers use innovative cooling technologies to create constant precision test conditions.

The CPUs are mounted directly onto Peltier heat sinks, which serve as primary cooling units. This technology guarantees extremely precise temperature control,

which is essential for the production of meaningful test results. In order to counter-cool these primary cooling units, air-cooled circulation chillers are used as secondary cooling units for multiple climate chambers. These systems provide the necessary cooling water and ensure that the test conditions remain stable over long periods of time. The high reliability and durability of the LAUDA circulation chillers are crucial in ensuring that the test procedures run smoothly.

Find the right device for your application

In accordance with the principle of ›modular engineering‹, LAUDA systems are planned and built precisely according to customer‘s wishes: process-oriented, customized and with precision control, meeting the strictest safety standards.

You can find out which devices and solutions we can support you with in the semiconductor industry in our new brochure.

Answer some questions and we will work out your individual constant temperature solution in the next step.

You are looking for Measuring instruments that combine precision, reliability and longevity confidently?

There are already three products on your comparison list.

To compare other products, please delete one of the products on your comparison list.