Energy-efficient and cost-saving

Developed with a focus on energy efficiency, the new LAUDA Ultracool circulation chillers make a pivotal contribution to reducing your operating costs. The newly developed devices allow energy costs to be reduced by up to 50 percent, depending on the operating conditions.

Innovative operating concept

Thanks to the innovative operating concept, the LAUDA Ultracool circulation chillers can be conveniently monitored and controlled from a distance – via a connected remote control or the integrated web server on a PC or laptop. A connection to the LAUDA Cloud allows device data to be saved, analyzed and used for remote maintenance.

Advanced technology for a broad range of applications

Extensive technical innovation and a significantly expanded range of functions characterize the various LAUDA Ultracool devices and additional equipment options. Custom options and a wide cooling output range make the new generation of LAUDA Ultracool circulation chillers the ideal solution for a broad range of industrial applications.

Then get in touch with us directly.

High energy saving and a short payback time

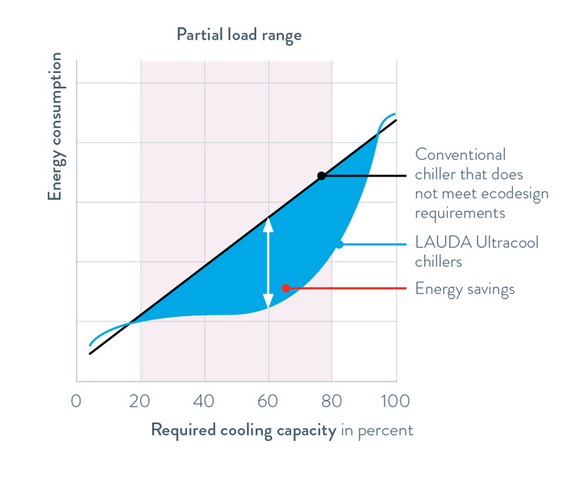

Depending on the operating conditions, the new circulation chillers are significantly more energy-efficient than conventional circulation chillers which are not Ecodesign-compliant.

A modern chiller that conforms with the EU Directive has clear advantages over older devices or products still in use and available outside the EU, which are not subject to the Directive. Some chillers exceed the required SEPR values for energy efficiency by some distance, such as the new generation of LAUDA Ultracool circulation chillers, which meet ecodesign requirements and incorporate a speed-controlled compressor, ventilator fan and electronic expansion valve.

Compliant with the Ecodesign Directive

The new LAUDA Ultracool circulation chillers comply with the Ecodesign Directive 2009/125/EC. This defines the limit values for energy efficiency that process circulation chillers must fulfill.

Short amortization times

The higher purchase price of an energy-efficient chiller, compared to a conventional device, typically amortizes between 1.5 and 2.5 years, thanks to savings made from reduced energy requirements.

The customer can determine the amortization time of a modern, energy-saving circulation chiller compared to conventional devices already in operation based on calculated energy savings, lower water/glycol costs, a tank content reduced by up to 80 percent and the lower maintenance costs of the new device.

Download our free white paper directly! In it, you will learn why our new process circulation chillers are also beneficial for your application.

Then get in touch with us directly.

Optimized for Industry 4.0

The new process circulation chillers are equipped with an LCD remote control as standard. An Ethernet interface for connection to a computer or local network (LAN) is also integrated as standard. In addition, the Ultracool devices can be controlled by means of a web server via a PC or even mobile devices - an internet connection is not necessary. All you need to do is to configure an IP address for the circulation chiller, which must be in the same network as the terminal device. The LAUDA Cloud enables monitoring and analysis of the device from any computer with an Internet connection – irrespective of location.

1. LCD remote control

2. Internal web server

3. LAUDA Cloud

Improved performance

Optimal cost balance

Simpler operation

Comprehensive standard equipment with many additional benefits

There are already three products on your comparison list.

To compare other products, please delete one of the products on your comparison list.