Das Kältesystem Kryopac wurde an die speziellen Bedürfnisse des Endkunden angepasst. Das Bild zeigt die fertige Anlage. (Bild: LAUDA)

LAUDA provides temperature control at -80 °C for freeze-dryer

LAUDA, the world market leader for temperature control equipment and systems, has been manufacturing customer-specific refrigeration systems for pharmaceutical companies for more than 50 years. The company has now completed a cryogenic cooling system for use in a pharmaceutical freeze-drying plant. This enables pharmaceutical substances to be gently frozen at -80 °C. The order was placed by Martin Christ Gefriertrocknungsanlagen GmbH, one of the world's leading freeze-dryer companies with more than 70 years of experience in this field. Martin Christ relies on the expertise of LAUDA for the reliable provision of the deep-freeze environment. A Kryopac Secondary Circuit Unit from LAUDA Heating and cooling systems, the plant construction division of the temperature control specialist, which plans and manufactures exactly according to customer requirements, provides the requisite cooling capacity.

Drugs and vaccines are essential for the treatment of diseases and the health of people worldwide. Since many drugs would only have a short shelf life when dissolved in water, the pharmaceutical industry relies on gentle freeze-drying for longer preservation. LAUDA was quickly chosen as the cryogenics expert for Martin Christ for the manufacture of a freeze-drying plant for an international pharmaceutical company. Apart from LAUDA's comprehensive know-how, the two companies have enjoyed a successful working relationship for many years. "We are specialists for extremely low temperatures and have been able to gain valuable experience in this field over many years", emphasizes Ralph Herbert, the project manager for Heating and cooling systems.

Liquid nitrogen provides temperatures down to -115 °C

Precise temperature control for the freeze-dryer is provided by a LAUDA Kryopac Secondary Circuit Unit, which enables cryogenic reactions to be safely controlled. The possibility of individual temperature control of the shelves and the ice condenser is of great importance in this refrigeration system. But the Kryopac, a heat exchanger specially developed for the evaporation of liquid nitrogen, is the heart of the system. Liquid nitrogen boils at -196 °C and is therefore particularly suitable as a refrigerant for applications which require extremely low temperatures. Depending on the design of the Kryopac system, temperatures down to -115 °C are possible in the secondary refrigerant oil circuit. The -80 °C required for the freeze-dryer is therefore reached quickly and exactly to the degree. Liquid nitrogen is also a non-flammable refrigerant which is preferred not only by the end customer but also by the pharmaceutical industry in general. Other advantages include economic, safety and environmental aspects, such as low investment costs and lack of waste products. Depending on the specification of the application, the nitrogen requirement can be decreased by adapting the control system designed by LAUDA, thereby significantly reducing operating costs.

The heat technology of the Kryopac system is derived from the proven LAUDA Heat Transfer Units used by many customers. These produce a temperature-controlled liquid flow and are delivered as a compact, fully insulated, ready-to-connect system with a control cabinet. The benefit: There are no freezing problems in the heat exchangers here. Precise temperature control, compact design and high plant availability were particularly important for Martin Christ's customer. The LAUDA Kryopac Secondary Circuit Unit also meets these requirements without any problems.

Freeze-drying makes use of a physical phenomenon

Freeze-drying is an extremely gentle preservation method, as the chemical properties of the source substances are not changed. All the active ingredients in pharmaceutical products are therefore preserved. This type of preservation is also used for sample preparation in laboratories, in the food industry or archeology, for example to preserve wet leather or wood.

The refrigeration system of the Kryopac system cools the shelves on which vessels filled with drugs are placed with a cooling capacity of 30 kW at -80 °C and freezes the pharmaceuticals in two and a half hours. Heat is supplied during evacuation, the removal of air by creating a vacuum. This results in a physical phenomenon called sublimation: The frozen water evaporates without liquefying. The drug is dried directly from the frozen state. The resulting water vapor is deposited on the ice condenser of the freeze-dryer in the form of ice crystals. The ice condenser is maintained at a temperature of -80 °C by the Kryopac system. A complete freeze-drying process typically takes 48 hours.

The Kryopac system was initially completely tested at LAUDA and then subjected to a further thorough inspection as a complete system at Martin Christ before the freeze-dryer was delivered to the end customer. However, this is not the end of the cooperation. As a result of the successful working relationship and implementation of this project, Martin Christ has already ordered two more LAUDA Kryopac Secondary Circuit Units.

LAUDA Puridest Destillierapparate sind je nach Modell in ein- oder zweistufigen Varianten erhältlich. Im Bild: Der Puridest PD 4 R mit internem Vorratstank.

LAUDA extends its portfolio with high-quality stills with the ‘GFL Technology’ quality mark

LAUDA, the world market leader for constant temperature equipment and systems for precise temperature generation, has extended its laboratory technology product range with the LAUDA Puridest stills product line. The devices with the 'GFL Technology' quality mark produce an ultra-pure, low-gas, sterile and pyrogen-free distillate with very low conductivity. Puridest stills are used in bacteriological and medical sample preparation and also in the preparation of cell and tissue cultures. They are also used for cleaning and sterilization processes, buffer solutions and microbiological and analytical applications. The distillate complies with the DAB regulations and the specifications of international pharmacopoeias. LAUDA Puridest stills also distill raw water of lower quality, separate pollutants, and reliably kill germs such as bacteria and viruses.

Low-maintenance and easy to use

LAUDA Puridest stills are available throughout the world in four high-performance product lines with 14 single- or two-stage model variants in the form of stainless steel or glass stills. Depending on the model, the devices are equipped with a storage tank and produce 2 to 12 liters of distillate per hour with conductivities down to below 1.6 µS/cm. Apart from their reliability and extremely long service life, LAUDA Puridest stills are characterized by their simple handling in the daily work in the laboratory. The stills are extremely easy to commission and operate. The ultra-pure water can be extracted directly after connection to the raw water and power supply. The devices are maintenance-free, because the glass stills automatically remove pollutants.

LAUDA Puridest stills with the "GFL Technology" quality mark

Decades of experience and technical development have set the standard: LAUDA Puridest stills are developed and manufactured by LAUDA-GFL. The company has been a member of the LAUDA group since December 31st, 2018 and is known throughout the world as a premium manufacturer of reliable laboratory technology. The use of the "GFL Technology" quality mark means that LAUDA is continuing the tradition of the GFL brand, which has been renowned for its quality and reliability in laboratories worldwide for more than 50 years.

Pure water: The Art of Distillation

Distillation is an effective and reliable way of producing pure water. The distinctive feature of distillation is that it only requires the input of energy. Compared with other auxiliary materials, such as absorbents or solvents, energy has the major advantage that it can be easily supplied to a system and removed again. As a result, stills require minimum maintenance. They are maintenance-free apart from regular cleaning. Distilled water, also referred to as aqua dest (lat. aqua destillata), is produced when steam condenses. This "pure water" is approx. 99.5 percent free of salts, organic substances, microorganisms, pyrogens and bacteria.

Neben den LAUDA Hydro Wasserbädern veröffentlicht LAUDA jetzt auch die LAUDA Varioshake Schüttelapparate unter dem Zusatz »GFL Technology«.

World market leader expands its portfolio with reliable shakers with "GFL Technology"

LAUDA, the world market leader for constant temperature equipment and systems, is expanding its product range of reliable laboratory devices for a wide spectrum of applications with the new Varioshake shakers. The LAUDA Varioshake product line comprises ten shakers in three sizes with five different shaking motions, as well as three shaking incubators in three sizes with a circular motion. Like the new LAUDA Hydro water baths, the Varioshake shakers feature “GFL Technology” and represent the many years of experience and outstanding quality of premium manufacturer GFL Gesellschaft für Labortechnik mbH, which became part of the LAUDA Group at the end of 2018. Equipped with modern LAUDA design and excellent performance data, the new GFL Technology laboratory devices stand for premium quality and precision.

LAUDA Varioshake: Shakers for reliable continuous operation

The LAUDA Varioshake shakers are reliable partners in many applications in the laboratory. They are used for mixing a variety of liquids or powders, prevent sedimentation or are used for oxygen enrichment and sample preparation. LAUDA Varioshake shakers are extremely user-friendly, robust and durable and are therefore the ideal companion for everyday work in the laboratory. Their sturdy, low-wear mechanical system ensures extremely smooth operation and reliable continuous duty. The electronics system controls the soft start. With a space saving of up to 35 percent compared to the previous model, Varioshake shakers are adapted to the limited space available in laboratories. All models of the LAUDA Varioshake shakers are presented in the new, modern LAUDA design.

LAUDA Varioshake shakers are available in versions with a load bearing capacity from 8 to 30 kg and work surfaces up to 676 x 540 mm. Depending on the model, the devices are equipped with user-friendly analog or digital control. The Varioshake VS 8 OE and VS 8 BE models stand out in particular: They are extremely compact and offer an extended ambient temperature range up to 60 °C (instead of the 50 °C typical for series production) for use in incubators. The shaking incubators from the LAUDA Varioshake product line offer a usable volume of 45 to 150 l with shaking areas up to 676 x 540 mm and excellent temperature stability of ±0.2 K. LAUDA Varioshake shakers are equipped with a large number of possible shaking movements. From orbital shakers for round vessels, such as Erlenmeyer flasks or petri dishes, and horizontal shakers to Varioshake overhead shakers with 360° rotation, the Varioshake product line offers movement patterns for a wide range of applications.

LAUDA Varioshake shakers with an extensive accessory range

The extensive accessory range enables the LAUDA Varioshake devices to be tailored to individual requirements. The modular system provides easy exchange and quick and easy adjustment to virtually any size or form of vessel. The range of accessories includes adhesive mats, universal attachments, trays, racks and clamps. In addition to this, almost all of the auxiliary equipment is globally compatible within the Varioshake shaker product range. Quick and easy retrofitting is therefore no problem.

"The LAUDA Varioshake shakers mean that we are adding another core piece of GFL laboratory technology to the extensive LAUDA portfolio. The designation 'GFL Technology' stands as a quality mark for quality and precision, coupled with new product features in a first-class design", explains Dr. Gunther Wobser, Managing Director of LAUDA. "With LAUDA Hydro and LAUDA Varioshake, we have already successfully introduced two LAUDA-GFL appliance lines in the modern LAUDA design this year. We will complete the reorganization in the course of this year."

LAUDA Variocool Umlaufkühler werden in der Temperierung von Bioreaktoren erfolgreich eingesetzt.

Precise temperature control from LAUDA makes an important contribution to the fight against the corona virus

The corona virus is changing our daily life and work in a way never before seen. Since the restrictions in public life currently continue to be largely maintained and can only be eased gradually, the pressure on global medical research to develop drugs, therapies and ultimately a vaccine against this novel virus is increasing. LAUDA, as a manufacturer of temperature control units and systems as well as laboratory equipment, contributes to the solution in dealing with COVID-19. As a long-standing supplier of professional temperature control technology with over 60 years of experience, LAUDA equips laboratories all over the world with highly accurate and reliable temperature control and laboratory technology. In times of the Corona Pandemic, an even more important part of LAUDA's expertise is found in the area of pharmaceutical production of active ingredients.

LAUDA temperature control units support companies in the chemical and pharmaceutical industry, for example in the commercial production of pharmaceutically and biotechnologically produced active ingredients - this becomes important, for example, in the production of a vaccine against the coronavirus in large quantities. An important step in this process is the temperature control of bioreactors. Here, microorganisms are cultivated under the best possible conditions, for example in the range of body temperature to 37 to 38 °C, and then suddenly cooled down. "In the field of bioproduction, we have been supplying all well-known customers for years. Especially our Integral process thermostats and the Variocool recirculating coolers with additional heating have become a kind of gold standard in the temperature control of bioreactors," explains Dr. Gunther Wobser, President and CEO of LAUDA.

For the mass production of a possible vaccine or supporting medication, the industrial division of LAUDA develops heating and cooling lyses for scale-up processes. These include process cooling systems for so-called "Freeze & Thaw" processes, in which active ingredients are deep-frozen in large tanks and shipped for further processing. "We are currently receiving enquiries from major technology companies in the USA who are using our industrial cooling systems for research on COVID-19," says Dr. Marc Stricker, the COO responsible for this area.

In addition to production, the storage of active ingredients plays an important role in combating the pandemic. LAUDA cryogenic equipment is used, for example, in the pharmaceutical industry for the production of vaccines and medications in order to store samples safely and over a long period of time.

LAUDA also offers solutions in the area of preparatory steps: "In the area of laboratory technology, we are currently receiving an increasing number of enquiries about LAUDA-GFL stills", explains Dr. Gunther Wobser. The distillation apparatuses of the youngest LAUDA subsidiary are used for the production of purified water for the manufacture of disinfectants as well as for the supply of autoclaves for sterilisation/autoclaving, e.g. of surgical instruments, components or tubes of respirators. So-called overhead shakers also help in the fight against coronavirus - the shakers are used to produce solutions for test kits for the extraction of DNA and RNA from a variety of sample materials such as serum, plasma, oropharyngeal or nasopharyngeal swabs (mouth, throat or nose) or other respiratory samples.

However, LAUDA's contribution does not end with its products and services. The company has also offered its support to the Corona Task Force for Medical Technology of the state of Baden-Württemberg, as well as to the well-known medical technology company Dräger in the production of urgently required medical devices. LAUDA also helped Corona helpers of the Main-Tauber Kreis with donations in their solidarity against the consequences of CO-VID-19: "We take the virus very seriously in our own company as well and have initiated strict rules and safety measures to protect the health of our employees and at the same time ensure the availability of our temperature control units worldwide," says Dr. Gunther Wobser. "Fortunately, we can still guarantee this at present. All of our employees are working flat out, either on site or from their home offices, to deliver first-class quality under the given restrictions for those who are urgently dependent on our products in the fight against COVID-19," adds CFO Dr. Mario Englert. "We are proud to be able to contribute to the solution of the Corona crisis with our daily work".

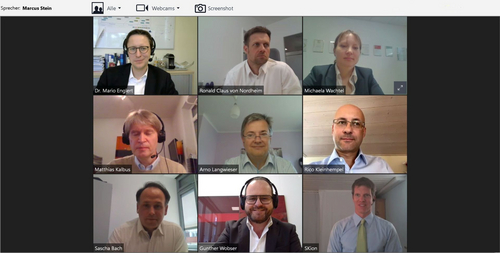

Invest-Gespräche in Zeiten von Corona: Markus Stein, CEO von watttron, begrüßte die Investoren per Videokonferenz. Auf dem Bildschirm, von links oben nach rechts unten: Dr. Mario Englert, Geschäftsführer LAUDA DR. R. WOBSER Beteiligungs-GmbH, Ronald Claus von Nordheim, CPO von watttron, Michaela Wachtel, COO von watttron, Dr. Sascha Bach, CTO von watttron, Dr. Matthias Kalbus, Beteiligungsmanager TGFS, Arno Langwieser, Investment Manager CNB, Rico Kleinhempel, Business Angel, Dr. Gunther Wobser, Geschäftsführender Gesellschafter LAUDA DR. R. WOBSER Beteiligungs-GmbH sowie Jan K. Verweyen, Beteiligungsmanager SKion GmbH

LAUDA intensifies involvement with innovative start-up watttron

The LAUDA DR. R. WOBSER GmbH & Co. KG, the world market leader for precise temperature control, has renewed its support for the Saxon technology start-up watttron. Together with other renowned investors, LAUDA is providing fresh capital of EUR 3.4 million in addition to expertise. LAUDA is thus underlining the importance of the successful cooperation with the young company from Freital near Dresden, which began in 2018. The multi-award-winning start-up company develops and manufactures intelligent heating systems that are able to heat with pinpoint accuracy. This is particularly important in the packaging industry, as the innovative process can save energy and material. Together with LAUDA, marketing opportunities in the fields of analysis, bio and laboratory technology and on the North American market are being worked on. In addition, both companies are working on a prototype that is not only capable of heating with pixel accuracy, but also of cooling.

With the current financing round, watttron aims to accelerate its own development, gain new partners on a global level and open up new industries such as biotechnology, chemistry or 3D electronics. LAUDA as a partner firmly believes in the success of the young company and is convinced of the joint partnership: »We have been watttron's cooperation partner for around two years because we have already seen and actively support the benefits of the patented heating technology beyond the packaging market in 2018«, says Dr. Gunther Wobser, President and CEO of LAUDA. »The positive development of recent years has confirmed our decision to continue investing in watttron.«