Dr. Gunther Wobser, President & CEO of LAUDA (right), together with the two managing directors – CFO Dr. Mario Englert (left) and COO Dr. Marc Stricker (2nd from left) – honored Jutta Mark (3rd from left) and Gabriele Wobser (2nd from right) for their 45th company anniversary. © LAUDA

Long-standing loyalty to the family business honored

LAUDA DR. R. WOBSER GMBH & CO. KG honored two exceptional employees for their 45 years of service to the company in a ceremony. Jutta Mark and Gabriele Wobser were honored in the presence of the LAUDA management for their decades of loyalty and outstanding achievements for the family-owned company.

Both jubilarians began their professional careers at LAUDA in 1980 and have helped shape the company's development over the past 45 years. Jutta Mark began her training as an office clerk on September 8, 1980, and built her career from the Export department to OEM Sales to Key Account Management, where she now takes care of key national and international customers. Gabriele Wobser, daughter of former LAUDA President & CEO Karlheinz Wobser, began her training as a technical draftswoman on September 15, 1980, and progressed from the Research and Development department to the Manager of Design in the Plant Engineering department. Her expertise in CAD design and project coordination makes her an indispensable pillar of the company. Both Jutta Mark and Gabriele Wobser have kept their knowledge up to date through continuous training and are valuable employees in their respective departments.

Dr. Gunther Wobser, President & CEO of LAUDA, praised the extraordinary achievements of both employees in his laudatory speech: “Jutta Mark and Gabriele Wobser embody the values of our family business in a special way. With their 45 years of loyalty and continuous professional development, they have played a decisive role in shaping LAUDA. Their expertise, commitment, and reliability make them indispensable pillars of our success.”

Dr. Wobser particularly highlighted Jutta Mark's international expertise, who cultivates global customer relationships through her language skills and many years of export experience, as well as Gabriele Wobser's technical expertise in CAD design and project coordination in plant engineering.

In recognition of their outstanding achievements, Jutta Mark and Gabriele Wobser received both the LAUDA certificate and the certificate of honor from the Chamber of Industry and Commerce. Dr. Wobser concluded by emphasizing: “Employees such as Jutta Mark and Gabriele Wobser demonstrate that loyalty, competence, and continuous development are the cornerstones of our family business. Their 45 years of service are impressive proof of the special bond between our employees and LAUDA.”

The double anniversary underscores the importance of long-standing employees for the continuity and success of the family-owned company LAUDA. Such extraordinary careers demonstrate the appreciation and trust that has grown between the company and its employees over decades. They also illustrate the stability and family atmosphere that characterizes LAUDA as an employer and forms the basis for sustainable corporate success.

Volker Mott, Barbara Schmitt, and Bernd Volkert (4th, 5th, and 6th from left) celebrate their 40th company anniversaries and decades of loyalty to the family-owned company LAUDA together with President & CEO Dr. Gunther Wobser (right) and (from left to right) Sandra Braun (Director Human Resources), Chris Moschüring (Purchasing Manager), Elmar Mohr (Works Council Chairman), Dr. Jürgen Dirscherl (Director Research & Development) and Dr. Lukas Braun (Mayor of Lauda-Königshofen). © LAUDA

LAUDA honors three long-serving employees

LAUDA DR. R. WOBSER GMBH & CO. KG honored three employees for their extraordinary 40-year company anniversaries in a special ceremony. Barbara Schmitt, Volker Mott, and Bernd Volkert began their careers at the family-owned company on September 9, 1985, and have played a key role in shaping the development of the global market leader for temperature control devices and systems over four decades.

In his laudatory speech, Dr. Gunther Wobser, President & CEO, praised the impressive career paths of all three jubilarians. Barbara Schmitt completed her training as an industrial clerk at LAUDA and initially worked in the switchboard and financial accounting departments before moving to human resources and payroll accounting in 2018. “Barbara Schmitt is characterized by great precision and a sense of responsibility. Her expertise in payroll accounting is invaluable to our company. With around 50 internal training courses, she always keeps her finger on the pulse,” emphasized Dr. Wobser. Sandra Braun, Director Human Resources, praised her willingness to learn and her reliability: “Barbara's work is characterized by a high degree of reliability – she is conscientious, calm, and precise, and has an eye on both the company and its employees.”

Volker Mott has undergone remarkable development within the company. After training as an industrial mechanic and later completing further training as a master craftsman and quality management technician, he worked in various areas – from assembly and quality management to marketing. For twelve years now, he has been at home in purchasing, where he contributes his high level of technical expertise. “Mr. Mott has always dared to think outside the box and has continuously acquired new skills. His versatile development within the company demonstrates his willingness to take on responsibility and face new challenges,” accentuated Dr. Wobser. Chris Moschüring, Purchasing Manager, added: “Purchasing benefits immensely from Volker's technical knowledge. Particularly noteworthy are his responsibility for first-class trainee support and his enthusiasm for change.”

Bernd Volkert has proven himself to be a real top performer with a passion for plant engineering. After completing his training as an energy equipment electronics technician and subsequently studying part-time to become a state-certified electrical engineer at the DAG Technical College in Würzburg, he gained extensive experience in research and development. He has been working in plant engineering since 1990 and has held a management position since 2009. “Mr. Volkert has pursued his career with determination and developed impressive technical expertise in the process. His various further training courses and his many years of commitment make him an indispensable employee. His enormous expertise across all types of systems and his analytical thinking in project planning are exceptional,” praised Dr. Wobser. Dr. Jürgen Dirscherl, Director Research & Development, emphasized: “Bernd Volkert has spent more than two-thirds of his life at LAUDA. His positive charisma, helpfulness, and high level of technical understanding in project planning are impressive.”

Dr. Lukas Braun, mayor of the city of Lauda-Königshofen, highlighted the special significance of high employee loyalty at LAUDA in his welcoming speech. He explained that the three anniversaries represent mutual recognition between the company and its employees. The high number of honors at LAUDA demonstrates a strong sense of community and significant team spirit. The family-owned company is characterized by loyalty and responsibility towards its employees and is an important employer for the city. In recognition of their achievements, the mayor presented the jubilarians with a certificate of honor from the state of Baden-Württemberg from Minister President Winfried Kretschmann and a gift of wine.

Works council chairman Elmar Mohr conveyed the greetings of the workforce and emphasized the similarities between the honorees: “All three completed their training at LAUDA and have remained loyal to the company for 40 years – despite taking different individual paths within the company.”

The three anniversaries impressively underscore the special culture of the family-owned company LAUDA, where long-term employee loyalty and mutual appreciation have been practiced for generations. Dr. Wobser presented all the jubilarians with LAUDA certificates as a token of appreciation for their decades of loyalty and exceptional achievements and wished them continued health, happiness, and many more successful years.

LAUDA President & CEO Dr. Gunther Wobser (center) is counting on his proven collaboration with Heinrich-Bignasse (left, Director Global Sales) and Bossart (right, Director Product Management & Service) to strengthen the company's market position. © LAUDA

LAUDA expands management responsibilities of Felix Heinrich-Bignasse and Enrico Bossart

LAUDA DR. R. WOBSER GMBH & CO. KG announces the expansion of the areas of responsibility of two executives. Effective July 1, 2025, Felix Heinrich-Bignasse will take over as the new Director Global Sales, assuming overall responsibility for the worldwide sales activities of the leading supplier of temperature control devices and systems. At the same time, Enrico Bossart will expand his responsibilities and, as Director Product Management & Service, will also be responsible for the central service division of the global market leader for precise temperature control.

The bundling of responsibilities will strengthen global customer-focused activities, further consolidate the market position and open new growth opportunities. In his new role, Felix Heinrich-Bignasse will be responsible for global sales activities for the entire range of services and will take over regional sales in addition to key account management. Enrico Bossart will be responsible for service in addition to his previous tasks in product management, including product marketing. This will achieve even closer integration between innovative services and service products and customer support. Digital service and sales via e-commerce solutions play a particularly important role here.

Dr. Gunther Wobser, the President & CEO who is responsible for customer activities, temporarily headed both departments himself. He praised the achievements of both executives: “In Felix Heinrich-Bignasse and Enrico Bossart, we have two proven leaders who have both demonstrated their skills over the past six years. The expansion of their areas of responsibility is recognition of their achievements to date and will further strengthen our market position.”

Felix Heinrich-Bignasse holds a degree in industrial engineering and studied at the University of Würzburg-Schweinfurt. He also holds a master's degree in International Business and Export Management from the University of Krems in Austria. Heinrich-Bignasse joined LAUDA in April 2019, initially working as Sales Specialist OEM. In February 2021, he became Acting Sales Manager OEM, and in March 2022, he was appointed as Director Key Account Management. His appointment to this management position marked his promotion to the executive board. His achievements to date include the successful establishment of key account management and sales responsibility for plant engineering. In his new role as Director Global Sales, Heinrich-Bignasse will drive forward international expansion and intensify cooperation with the regional sales teams.

Enrico Bossart studied International Technical Management at the Mosbach Cooperative State University. He then worked in product management at a leading German manufacturer of industrial measurement technology. The graduate engineer has been successfully strengthening the LAUDA team as Director Product Management since April 2019. On March 1, 2022, he was appointed Division Manager and joined the management team. His achievements to date include the implementation of the 5-year best-warranty and the successful launch of the new LAUDA Universa product line. With the assumption of responsibility for service, Bossart will use his extensive product knowledge to develop innovative service solutions and further increase customer satisfaction.

With this restructuring, LAUDA is bundling responsibilities in sales and service and expects to increase sales in the service area through new initiatives. With these personnel decisions, LAUDA is optimally positioned for future challenges in the market and underscores its confidence in its own management.

LAUDA bath circulators assist in the development of new adhesives

About Chemique Adhesives

Chemique Adhesives is a trusted UK manufacturer of industrial adhesives, celebrating its 40th Year in 2025. They have been at the forefront of providing industry-leading adhesive solutions whilst delivering first class service and support to its the diverse needs of its customers.

Over the years, they have continuously evolved and expanded their product portfolio to cater for many industries including automotive, commercial manufacturing, construction, foam, furniture, panel lamination, raised access flooring, and more.

Chemique Adhesives brands include:

Aerotak – Aircraft Seating Adhesives

Axil – Manufacturing Adhesives

Polyped – Raised Access Flooring Adhesives

ProAqua – Foam Bonding Adhesives

Protak – Bedding, Packaging & Woodworking Adhesives

Solfre – Laminating Adhesives

Turftak – Artificial Turf Adhesives

SABA – Mattress Adhesives

Formulations to suit

Chemique Adhesives work closely with its customers to provide formulations that suit their particular needs. Chemique’s experienced chemists and engineers are on hand to provide new and innovative solutions to suit all adhesive and application requirements, to provide the most cost-effective result possible.

Chemique’s well equipped research and development laboratory allows their chemists to carry out multiple tests and recommend the correct adhesive and application process specific to a customers’ needs.

These stringent testing procedures allow them to develop superior industrial adhesives, ensuring the highest customer satisfaction, whilst remaining at the forefront of adhesive technology.

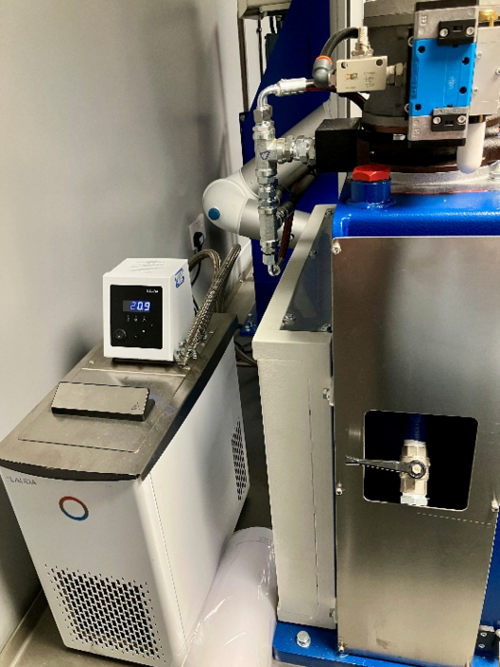

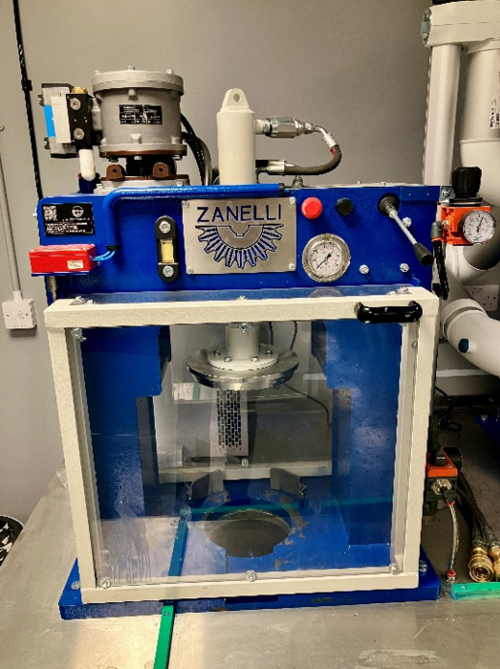

LAUDA’s bath circulators form an important part of this R&D laboratory, providing accurate temperature control to the laboratory scale mixers and dispersers– see images below. This allows the chemists to test and simulate conditions on new and existing products as part of the validation process and in preparation for scale up in their manufacturing facilities.

The LAUDA Alpha RA 8 bath circulators are compact for a benchtop unit, reliable and can provide temperature control from -25 degC up to +100 degC, making it the ideal temperature solution the adhesives need to be worked at.

Simon Cashmore, Operations Manager

“We have been happy with the performance and reliability of the four LAUDA units we have in our laboratory. As we have expanded our facilities, we have been more than happy to turn to LAUDA for additional units, as they are easy to operate yet provide us with all the functionality we require”.

If you would like to find out how we can support your laboratory testing, please get in touch with our experts today:

Remember to visit our website for immediate specifications and technical information

LAUDA received the EcoVadis Silver Medal in March 2025, placing it among the top 15 percent of all companies worldwide assessed in the field of sustainability. © LAUDA

LAUDA earns silver medal from EcoVadis

LAUDA DR. R. WOBSER GMBH & CO. KG, the world's leading manufacturer of temperature control units and systems, has been awarded the silver medal by EcoVadis. With a score of 70 out of a possible 100 points, LAUDA ranks among the top 15 percent of all companies worldwide and thus underscores its commitment to sustainable business practices.

EcoVadis is considered the global market leader in sustainability ratings. The organization evaluates companies based on 21 detailed sustainability criteria covering four key areas: Environment, Labor and Human Rights, Ethics, and Sustainable Procurement. To date, more than 85,000 companies worldwide have undergone the rigorous EcoVadis assessment process, which is based on international standards, including the ten principles of the UN Global Compact, International Labor Organization conventions, and the ISO 26000 standard.

LAUDA receives this award in recognition of its comprehensive sustainability management efforts and strategic sustainability initiatives. “This recognition confirms our long-standing conviction that sustainable business practices and entrepreneurial success go hand in hand,” emphasizes Dr. Gunther Wobser, President & CEO of LAUDA. “Receiving the EcoVadis Silver Medal is an important milestone in our journey to becoming a more sustainable company.”

A key component of this success was the publication of the 2023 sustainability report, which was released at the end of 2024. This transparent reporting allowed LAUDA to document and demonstrate the quality and scope of its sustainability activities to EcoVadis. “The systematic documentation of ESG activities in our first sustainability report was a decisive factor in this assessment,” explains Dr. Marc Stricker, Managing Director of LAUDA and responsible for quality and environmental management. “We demonstrated to EcoVadis that we implement concrete actions that we measure and communicate transparently.”

The improvement in the EcoVadis rating was made possible by several measures that LAUDA systematically implemented. The company developed more detailed sustainability policies and significantly expanded the collection and publication of key figures relevant to EcoVadis. For the first time, the company published comprehensive reports on environmental and social aspects. In addition, a CSRD report was prepared in accordance with the new European reporting standards. This systematic approach enabled LAUDA to optimize its internal processes and significantly increase its external transparency.

“We are particularly proud that the more detailed specifications from LAUDA and the extended recording of key figures have led to measurable improvements”, adds Dr. Stricker. “This demonstrates the efficacy of our comprehensive approach to sustainability management and validates our strategic direction.”

For the future, LAUDA plans to make targeted use of the insights gained from the EcoVadis assessment process in customer discussions. The family-owned company will further refine its sustainability strategy and continue its ESG reporting.