Image: The newly built production site in Terrassa, Spain.

Celebratory inauguration of the new production site in Terrassa, Spain

The Spanish subsidiary of LAUDA DR. R. WOBSER GMBH & CO. KG, LAUDA Ultracool, SL, has officially inaugurated its new production site with a celebratory ceremony in Terrassa, near Barcelona. In doing so, the temperature control specialist has successfully completed its first construction project abroad – and its first greenfield construction of an entire production facility. The family company has invested around seven million euros in the new-build in Spain, and created around 4,000 m² of new production areas and almost 1,000 m² of office space on the 9,000 m² site. As a result, the Spanish subsidiary has doubled its production capacities for LAUDA Ultracool circulation chillers, to meet growing demand worldwide for energy-efficient industrial cooling. The expansion of Spanish subsidiary is strategically aligned with the ambitious Drive250 strategy project, with which the world market leader aims to more than double its revenue within five years.

Along with the workforce and the Managing Director of LAUDA Ultracool, Xavier Armengol, the festivities were attended by high-ranking representatives from Germany, including President & CEO Dr. Gunther Wobser and his father Gerhard Wobser, as well as Managing Directors Dr. Marc Stricker and Dr. Mario Englert. Regional representatives including the Mayor of Terrassa Jordi Ballart and Deputy Mayor Núria Marin, and Patrick Heinz, the Deputy Consul General of the German Consulate General in Barcelona, also took part in the event. In their speeches, Ramon Talàmas, President of the Terrassa Chamber of Commerce, and Joan Romero, Representative of the Catalonian Government and CEO of ACCIO, an organization to ensure the competitiveness of Catalonian businesses, as well as Antoni Abad, President of the CECOT Entrepreneurs’ Association, praised the contribution and commitment of the world market leader LAUDA to the burgeoning economic region of Catalonia.

“In recent years, LAUDA Ultracool has grown steadily and successfully positioned itself on the market with modern, energy-efficient circulation chillers,” said Dr. Marc Stricker, summarizing the developments of the last few years. “The new build will create urgently needed capacities for our biggest overseas subsidiary, both in production and for the further expansion of the product line. Accordingly, this important investment is perfectly in line with our Drive250 growth strategy.”

“Like in 2011, when we acquired the Spanish subsidiary, we are showing courage and investing during difficult times,” remarked Dr. Gunther Wobser during his festive speech. “That’s why it is all the more important that we as a company send a visible signal of confidence and determination. By doing so, we can write our success story together.”

Image: The Managing Directors of Beun de Ronde, Corné Reuvers and Mike Klinkenberg, with Dr. Gerhard Wobser and the President & CEO of LAUDA, Dr. Gunther Wobser (from left to right)

First LAUDA agency Beun de Ronde is awarded the Dr. Rudolf Wobser Medal

The Dutch laboratory dealer Beun de Ronde B.V., a provider of scientific equipment with an impressive history going back 100 years, has been one of LAUDA DR. R. WOBSER GMBH & CO. KG.’s most reliable partners for decades. Since 1958, the two family companies have worked together without . Beun de Ronde was LAUDA’s first agency abroad, meaning it has been at the world market leader’s side almost from the very beginning. After the death of the two company founders Beun and de Ronde, their long-standing, trusted colleague Joop Klinkenberg took over the shares and the company management, which he later passed down to his son Mike. To honor this extraordinary and close partnership, the current Managing Director Mike Klinkenberg has been awarded the Dr. Rudolf Wobser Medal. At a celebratory dinner at the company headquarters near Amsterdam, the President & CEO of LAUDA, Dr. Gunther Wobser, presented the award in the presence of his father, Advisor and Shareholder, Dr. Gerhard Wobser, and the Managing Director of Beun de Ronde, Corné Reuvers.

Dr. Gunther Wobser handed over the medal in person. This time, the occasion was a first: “The relationship between LAUDA and Beun de Ronde is a very special one, because it was the first agency that LAUDA signed a contract with on August 15th, 1958. The collaboration goes back even further, as company founder Dr. Rudolf Wobser knew Jan de Ronde from his previous work. Especially in the early days of our company, Beun de Ronde played a significant role in our success, for which I would like to thank him on behalf of everyone involved. To this day, our partnership is the foundation of our shared economic success and can undoubtedly be regarded as a shining example of an international, neighborly collaboration between two family companies.”

The Dr. Rudolf Wobser Medal, which is made of real gold, was created for the occasion of the 60th company anniversary in 2016 and is awarded to individuals who have made an extraordinary contribution to the family company. For example, employees who have belonged to the company for over 50 years are honored with the award. In total, 16 Dr. Rudolf Wobser Medals have been awarded. Mike Klinkenberg will be the first person outside the company and outside Germany to receive this distinguished accolade.

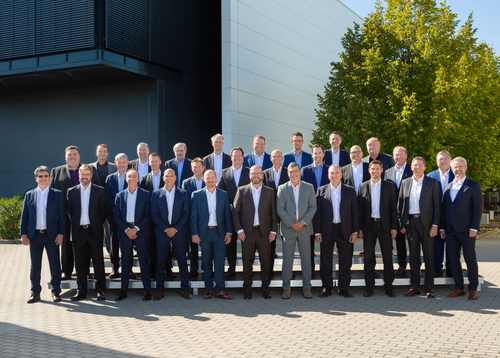

LAUDA executives at the World Jour Fixe 2022

International LAUDA management team strengthens teamwork at strategic meeting

2022 – For the first time since 2019, the managing directors of the twelve overseas subsidiaries got together with the senior management of LAUDA DR. R. WOBSER GMBH & CO. KG for the World Jour Fixe at the company headquarters in Lauda-Königshofen. In the previous two years, the strategic meeting of all the senior managers had to take place online due to the pandemic.

LAUDA's international management team traditionally meets twice a year, to discuss directive projects, goals and plans of the limited partnership and all its subsidiaries. In intensive workshops and training sessions, the participants develop strategic goals, evaluate milestones and create synergies for the world market leader's global business. Alongside an extensive development analysis of the individual business fields and the upcoming annual plan for 2023, the comprehensive strategy project Drive250 was at the top of the agenda. Under this title, the family company has set itself ambitious growth targets. For example, the number of LAUDA employees is set to double worldwide, from 530 at present to over 1,000 by 2026. The company also wants to increase its turnover from the current level of around 100 million euro to 250 million euro in the five-year period under consideration.

“Direct, in-person discussion with each other is an important factor in LAUDA’s company culture,” explains President and CEODr. Gunther Wobser, emphasizing: “We are in an important phase of our strategic realignment, which is made more difficult by the current geopolitical developments. That’s why now, more than ever, all international forces need to work together to carry forward our shared vision of making the world a better place with precise temperatures.”

After an intensive three days, the organizers and 29 participants were left with a positive overall impression of the event. On top of the strategic work, there was no shortage of collegial interaction between the participants, including a traditional visit to the Königshöfer fair and a cycling trip to the neighboring town of Bad Mergentheim with a mini golf tournament.

Perfect temperature control for the process industry: LAUDA shows industrial heat transfer systems at ACHEMA. © lauda.de

LAUDA presents innovations in temperature control at ACHEMA

ACHEMA, the world's leading trade fair for the international process industry, will gather experts, users and the trade press from all over the world in the Frankfurt exhibition halls from August 22 to 26, 2022. The LAUDA DR. R. WOBSER GMBH & CO. KG will present digital innovations from temperature control technology at its stand in Hall 4.0, Stand C26, and provide an insight into the possibilities in hydrogen cooling - one of the trend topics at this year's ACHEMA. In contrast to its previous trade fair appearances at ACHEMA, LAUDA is deliberately concentrating this year on the focal points of process engineering and process industry in order to bring its own experience and portfolio in the field of industrial temperature control to the fore.

»The process industry with its diverse applications and future-oriented developments is one of our most important target markets,« explains LAUDA CSO Dr. Ralf Hermann. »Thanks to our decades of work in this field, we have a profound understanding and the necessary expertise for the most demanding temperature control tasks in process technology. Accordingly, we are delighted to finally be able to present our latest developments to our customers and partners again in a presentable setting and provide new impetus.«

Process thermostats with native app control and digital products from LAUDA

In the field of reactor temperature control, LAUDA presents the new generation of LAUDA Integral process thermostats, powerful temperature control units with intuitive control via mobile devices. LAUDA is bundling its digital innovations under the trade fair motto EMPOWERING EXCELLENCE. FOR A BETTER FUTURE. With cleverly thought-out further developments in temperature control technology that optimally complement user processes and make them possible in the first place, LAUDA supports its customers in industries such as chemicals, pharmaceuticals, electromobility and hydrogen in improving the world with precise temperature control.

The smart networking of process technology and temperature control technology continues to advance with LAUDA.LIVE. With this digital platform, LAUDA temperature control solutions become fully networked and intelligent IoT devices. The digital products provide users with comprehensive asset management capabilities and smart analytics and monitoring tools, optimizing LAUDA equipment uptime, reliability and performance. A demonstration of LAUDA.LIVE awaits visitors at the LAUDA booth at ACHEMA.

LAUDA is demonstrating its extensive know-how in the process industry at ACHEMA with a LAUDA ITH heat transfer system for process temperature control. The industrial system offers working temperatures up to a maximum of 550 °C and a heating capacity of 3 - 500 kW, making it ideally equipped to handle individual temperature tasks in process industry applications. LAUDA experts on site will be happy to answer visitors' questions and discuss customized temperature control solutions.

If you would like a personal interview, our CEO, Dr. Gunther Wobser will be available from 24-26.8.22 and our Director of Product Management, Enrico Bossart will be available from 22-24.8.22 at the trade fair. Please contact us regarding this as early as possible so that we have sufficient time to plan and spend time with you and your questions. Thank you very much.

![Picture: Group picture Innovationsregion Hohenlohe [Translate to Englisch:] Group picture Innovationsregion Hohenlohe](/fileadmin/_processed_/a/c/csm_LAUDA_Gruppenbild_Innovationsregion_Hohenlohe_web_0246183c61.jpg)

Guido Rebstock, Managing Director of Innovationsregion Hohenlohe e. V., Dr. Gunther Wobser, President and CEO of LAUDA, Dr. Stefanie Leenen, Chairwoman of Innovationsregion Hohenlohe e. V. (l. to r.) © Innovationsregion Hohenlohe e. V.

LAUDA new cooperation partner of Innovationsregion Hohenlohe

LAUDA DR. R. WOBSER GMBH & CO. KG is a new cooperation partner of the association Innovationsregion Hohenlohe e. V. In this way, the global market leader wants to strengthen its own innovation activities and also supports the securing of locations and structural promotion in the extended region. Both partners want to use synergies and work together to promote and retain skilled workers in so-called MINT professions.

"As a family business with strong roots in the region, one of our most important tasks is to inspire skilled workers and young talent for our wonderful home region - especially in times of a shortage of skilled workers. Although we are based outside of Hohenlohe in the Main-Tauber district, I have been following the admirable activities in our immediate neighborhood with great enthusiasm since the company was founded over twenty years ago. As cooperation partners, we can now work together to achieve our common goals," emphasizes LAUDA's President and CEO, Dr. Gunther Wobser. In addition, LAUDA bundles innovation activities outside its core business in its subsidiary new.degree. In the company's own Innovation Lab, the company drives forward ideas from employees as well as technology and service innovations from start-ups and digital initiatives in exciting search fields for future-oriented temperaure control.

With the Brainstation project, which is to be built in the former Lauda train station in the heart of the Main-Tauber district, the ambitious entrepreneur himself is pursuing the goal of working with other entrepreneurs to get young people excited about entrepreneurship, digitization and innovation - and ultimately to prevent them from migrating to metropolitan areas. As the region's innovation center, Brainstation will offer event space, creative zones, a co-working area, a café, boarding house, offices and a technology museum. With Futurelabs gGmbH and the Makerspace, children and young people will have an exciting place to discover their own talents. This creates the best conditions for successful collaboration with the Hohenlohe Innovation Region.

"We are very pleased to welcome the global market leader LAUDA as a new cooperation partner of Innovationsregion Hohenlohe e.V.," explains the chairwoman of Innovationsregion Hohenlohe e. V., Dr. Stefanie Leenen. "The globally active and innovative company with the impressive dynamics is a real enrichment for our network and fits perfectly with the goals that the Innovation Region has set for itself."

Since its foundation in 2000, the Initiative Innovationsregion Hohenlohe e. V. has set itself the task of maintaining the region with its large number of world market leaders as an attractive location for the future. Today, the innovation region consists of 26 members, 19 of which are manufacturing companies and seven service providers. Among other things, the initiative is involved in schools and works closely with politics, ministries, administration, science and educational institutions.