Modular engineering

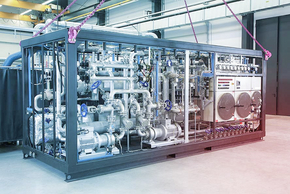

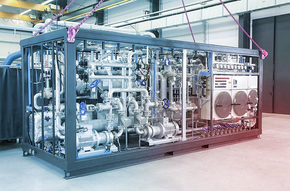

In accordance with the principle of "modular engineering,” LAUDA plans and builds systems precisely in accordance with the customer's wishes: process-oriented, made-to-measure and precisely in accordance with the regulations, and with compliance with the strictest of safety standards. Within the temperature range from -150 to 550 °C, LAUDA systems heat and cool with an accuracy of up to one tenth of a degree Celsius. Since the requirements for constant temperature equipment are continuously growing, the modern LAUDA heating and cooling modules are also flexible as far as expansion and modification are concerned.

Project planning is our specialty. Working closely together with our customers, we design customized systems during the planning process. The keyword is modular engineering. With proven building blocks that are put together for the application, you get custom-tailored solutions. Matching of target and actual values requires precise planning of all interfaces. Each individual LAUDA planning component has been proven many times over and undergoes continuous further development. This is how we can guarantee a high quality standard.

Our service for you

Answer a few questions and we will provide you with

an individual temperature control solution in the next step.

Consumer

Three-way valve

Pump

Electric heaters

Benefits of our heating and cooling systems

Basic building block – expert advising

At LAUDA, our specialists will take care of you from the very beginning. We know that the right temperature determines the quality of the final product, and we advise you individually. This is where we can reap the benefits of our experience with many successful systems. That's why we take a lot of time for this step. We have industry knowledge and project management experience with technologically demanding systems. Expert advising is the prerequisite for successful development, on-time production and customer satisfaction.

The common element – modular engineering

Project planning is our specialty. Working closely together with our customers, we design customized systems during the planning process. The keyword is modular engineering. With proven building blocks that are put together for the application, you get custom-tailored solutions. Matching of target and actual values requires precise planning of all interfaces. Each individual LAUDA planning component has been proven many times over and undergoes continuous further development. This is how we can guarantee a high quality standard.

Custom systems – to the highest quality standard

The best planing is worthless without solid implementation. Our production specialists are experienced and know exactly how to implement special customer requests in heating and cooling systems. Thanks to our employees’ continuous training and education and the application of all relevant standards, all system have one thing in common: high quality and excellent performance data. All material qualities and technical features of the components are documented in detail and can be traced at any time.

Optimal interplay – LAUDA plug & play

Since the heating and cooling systems consist of ready-to-assemble units, they only have to be “docked” on-site. During planning, transport, incorporation and set-up are already considered. Questions of assembly, piping, insulation, safety technology and explosion protection must be clarified in advance. LAUDA specialists are up-to-date here and will advise you expertly.

Test run – putting devices through their paces

Complete system test before delivery in the LAUDA test field; system with CE mark

• Pressure and leakage test

(heat carrier system+ cooling system according to AD 2000 directive)

• Function test with load change

• Testing of control accuracy

• Test run at max. and min. working temperature

• Calibration of the temperature sensors

• Testing of all safety-relevant components according to EC directive

• Test log (proof of performance data)

Reliable service – close to you, worldwide

LAUDA heating and cooling systems are designed for continuous and proverbially low-maintenance

operation. Nevertheless, international regulations and safety ordinances require regular maintenance. A maintenance plan that is custom-tailored to the special system can best meet the requirements in question. Our experienced service technicians perform this regular maintenance. Our qualified partners assist us abroad. For the operator, the system is thus always maintained in accordance with regulations and in a verifiably safe manner when industrial health and safety ordinances require periodic inspections. In special cases, our service team can be available to you within 24 hours.

Certifications

LAUDA systems are used all over the world for temperature control. Comprehensive full documentation for all individual parts and the necessary safety units on the installation are necessary to guarantee a seamless certification process.