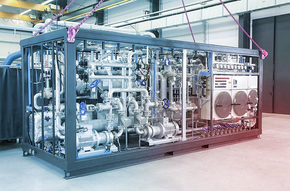

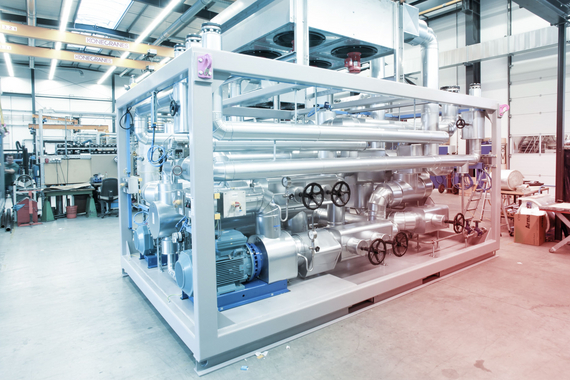

Depending on the required outflow temperature, heat transfer units use either thermal oil, water or water/glycol as the heat carrier. They are electrically heated and generate a temperature-controlled liquid flow. Heating and cooling systems in the heat transfer unit line always consist of the electric heater module and a maximum of one additional heat exchanger module (cooler). In this version, or in combination with a process cooling unit, a heating and cooling system is created with an extended working temperature range.

TECHNICAL DATA FOR LAUDA HEAT TRANSFER UNITS

| Features | ITH 150 | ITH 250 | ITH 350 | ITH 400 | ITH 600 |

|---|---|---|---|---|---|

| Heat carriers | Thermal oil | ||||

| Working temperature (°C) | max. 400 | ||||

| Pump output (m³/h) | 0,5 … 2 | 2 … 4 | 4 … 10 | 10 … 30 | 30 … 80 |

| Heating output (kW) | 3 ... 6 | 9 ... 12 | 18 ... 50 | 60 ... 100 | 125 ... 500 |

| Cooling | Water, brine or air-cooled heat exchangers | ||||

| Min. dimension (mm) | 500 x 800 x 1000 | 500 x 1000 x 1200 | 600 x 1000 x 1500 | 600 x 1500 x 1500 | 1000 x 1500 x 1900 |

| Max. dimension (mm) | 600 x 1500 x 1500 | 1000 x 1500 x 1900 | 1300 x 1900 x 2000 | ||

| Features | ITHW 150 | ITHW 250 | ITHW 350 | ITHW 400 | ITHW 600 |

|---|---|---|---|---|---|

| Heat carriers | Water, water/glycol | ||||

| Working temperature (°C) | max. 200 | ||||

| Pump output (m³/h) | 0,5 … 2 | 2 … 4 | 4 … 10 | 10 … 30 | 30 … 80 |

| Heating output (kW) | 6 ... 12 | 18 ... 24 | 30 ... 50 | 60 ... 100 | 125 ... 500 |

| Cooling | Water, brine or air-cooled heat exchangers | ||||

| Min. dimension (mm) | 400 x 800 x 1000 | 500 x 1000 x 1500 | 500 x 1000 x 1500 | 600 x 1500 x 1800 | 1000 x 1500 x 1900 |

| Max. dimension (mm) | 600 x 1500 x 1500 | 1000 x 1500 x 1900 | 1300 x 1900 x 2000 | ||

Your advantages at a glance

Digital temperature controllers

for the control of consumers/product temperature, as well as outflow temperature

Infinitely controlled electrical stainless steel heating bodies

So that the heating output is adjusted to the actual energy requirements and a long service life of the thermal oil and heating elements is guaranteed

Automatic shut-off valve in the cooling water inflow

To prevent contamination of the heat exchanger

Hermetic model without gaskets

So that oil and water are not mixed

Simple replacement of the heat exchanger

With water, brine or air-cooled stainless steel plate-heat exchanger and tubular heat exchanger in a flange model

FAT (Factory Acceptance Test) in the customer's presence

For checking that the systems are designed for customer requirements and initial training and test run even before delivery